How to Install a Tachometer on a Small Engine: A Complete Guide

Share

Every tech professional or enthusiast knows the significance of monitoring engine performance. One vital tool that plays a significant role in this is the tachometer. Understanding 'how to install a tachometer on a small engine' is essential, especially for those involved in mechanic projects or small engine repairs. This article will take you through the process step-by-step, ensuring you grasp the intricacies involved.

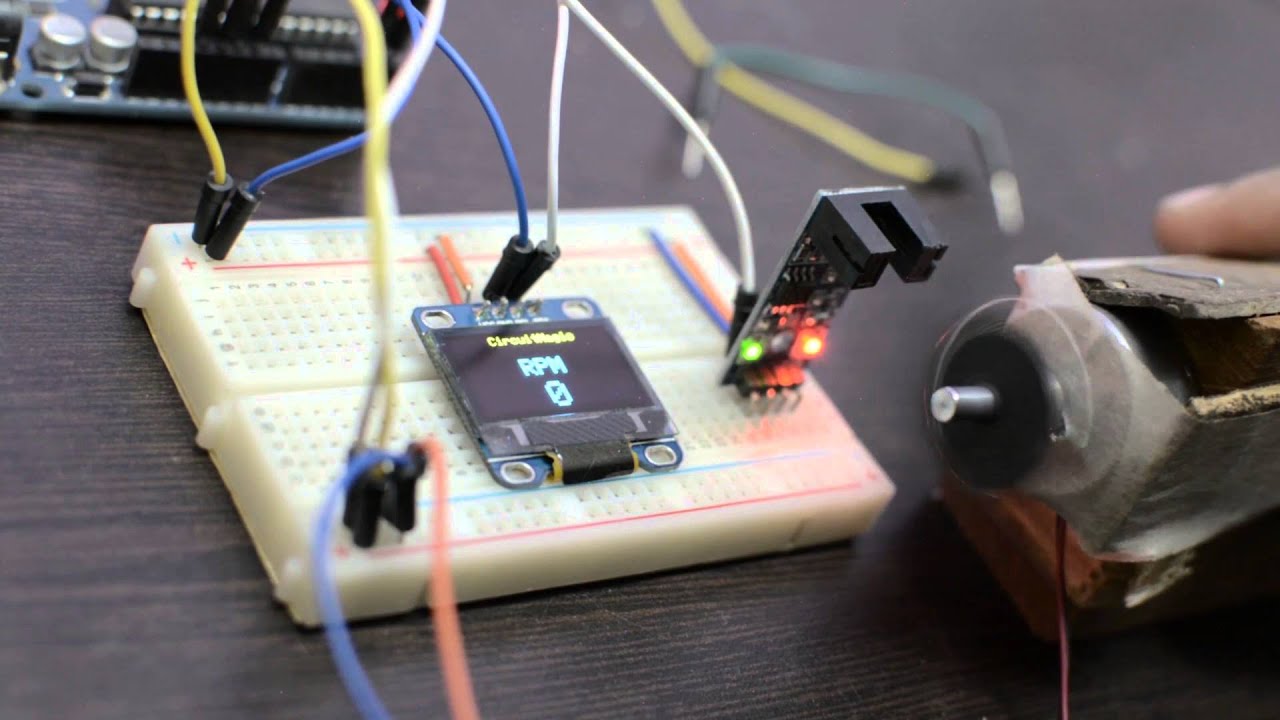

Not only does a tachometer measure the engine's RPM (revolutions per minute), but it also helps you optimize the engine's performance, prolong its life, and improve efficiency. Installation might seem daunting, but with our easy-to-follow guide, you'll be well-equipped to tackle the project yourself. Let's dive deeper into the essentials of tachometer installation!

Understanding Tachometers

A tachometer is a device used to measure the rotational speed of a shaft or disk. The readings provided by this device are crucial in various parts of the automotive sector as they allow for better engine management. There are two primary types of tachometers: digital and analog. Both serve the same purpose but may vary in terms of accuracy and display method.

Types of Tachometers

Tachometers can be categorized into two common types:

- Digital Tachometers: These devices use an electronic sensor to provide a digital readout of the engine's RPM.

- Mechanical Tachometers: These utilize gears and needles to represent RPM on an analog scale.

Tools and Materials Needed for Installation

Before embarking on the installation process, ensure you have the following tools and materials:

- New tachometer

- Wrench set

- Screwdriver set

- Electrical tape

- Wire stripper and crimper

- Drill and drill bits

- Owner's manual for the small engine

How to Install a Tachometer: Step-by-Step Guide

Step 1: Read the Owner's Manual

Before you proceed with the installation, it is crucial to consult your engine's owner's manual. Different engines may have unique requirements, and knowing the specific guidelines can help streamline the process.

Step 2: Prepare the Area

Make sure you're working in a well-ventilated area, and gather all your tools. A clean workbench will prevent any unnecessary complications during the installation.

Step 3: Disconnect the Battery

Safety should be your top priority. Disconnect the battery before commencing installation to eliminate the risk of electrical shock or short circuits.

Step 4: Mount the Tachometer

Choose a suitable location on your small engine to mount the tachometer. Ensure it is visible during operation. After determining the appropriate location, use the drill to create holes for mounting screws. Secure the tachometer with screws and ensure it is tightly in place.

Step 5: Connect the Wires

Every tachometer will come with a wiring diagram. Follow the guide to connect the wiring correctly. Typically, you will have several wires to connect: power, ground, and signal wire. The signal wire should connect to the ignition coil to pick up RPM readings.

Step 6: Reconnect the Battery and Test

After finishing the wiring connections, safely reconnect the battery. Turn on the engine and start monitoring the tachometer to ensure it reads correctly.

Common Issues and Troubleshooting

If your tachometer is not functioning as expected, consider the following common issues:

- Incorrect Wiring: Double-check your wiring connections with the provided schematic.

- Power Supply: Ensure there is power running through to the tachometer. Check the fuses to ensure they are intact.

- Engine Compatibility: Not all tachometers work with every engine. Research prior to purchase for compatibility.

The Importance of Tachometers

Using a tachometer can profoundly affect your engine's performance. It can prevent issues like over-revving, which could lead to catastrophic engine damage. For those interested in learning more about the importance of a tachometer, visit this important guide.

Conclusion

Installing a tachometer on a small engine may seem like a challenge, but by following these steps, you can successfully complete the task yourself. Beyond merely providing RPM readings, a tachometer offers insights into your engine's performance, ultimately allowing you to make modifications for better efficacy.

With this guide on 'how to install a tachometer on a small engine', you are now better equipped for your project. Take the plunge, and you'll not only learn a new skill but also enhance your understanding of engine management.

Frequently Asked Questions (FAQs)

Why is it important to install a tachometer?

A tachometer provides vital data regarding engine performance, allowing you to prevent over-revving and optimize engine health.

Can I install a digital tachometer on an older engine?

Yes, digital tachometers can typically be installed on older engines, but compatibility should be checked beforehand.

What if my tachometer reads incorrectly?

Incorrect readings may result from faulty wire connections or compatibility issues. Always verify wiring and installation.

For more insightful information on tachometers, check out this blog on tachometers.