How to Use Non Contact Tachometer for Accurate Readings?

Share

In today's high-tech world, knowing precisely how to measure rotational speeds is vital in various fields. Whether you are a tech professional or an enthusiastic hobbyist, understanding how to use non contact tachometer can enhance your skills immensely.

A non contact tachometer is a device designed to measure the rotational speed of an object without needing to touch it. This can be particularly beneficial in situations where direct contact would be impractical or impossible. With the advancement of technology, using a non contact tachometer has become easier and more efficient, allowing for precise measurements that are crucial in many applications.

Understanding Non Contact Tachometers

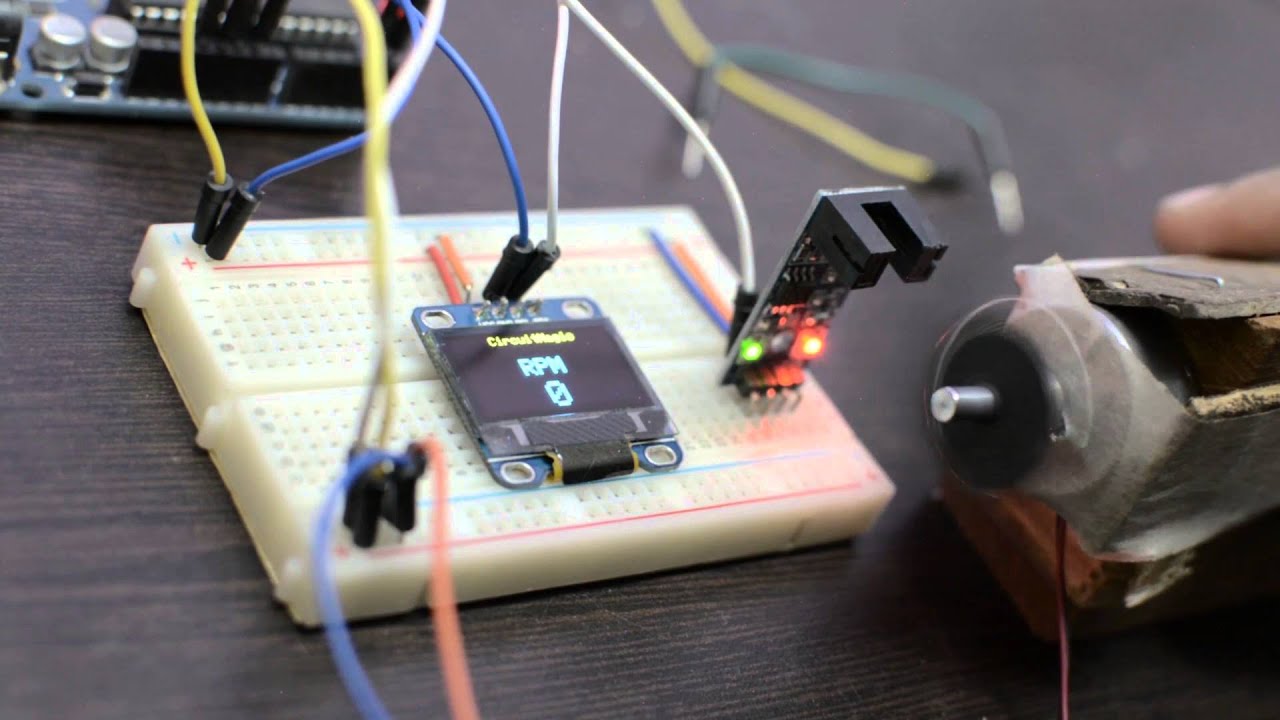

At its core, a non contact tachometer utilizes a laser or optical sensor to detect the speed of a rotating object. It measures the time it takes for the reflective surface of an object to pass by the sensor, converting this time into a speed measurement. This technology ensures that the readings are not affected by the physical properties of the rotating object.

Types of Non Contact Tachometers

There are primarily two main types:

- Laser Tachometers: These are widely used in industrial settings. They provide highly accurate measurements and can function well over long distances.

- Optical Tachometers: These devices use a light source to measure rotations. They require a reflective tape on the rotating surface to capture accurate readings.

Key Components of a Non Contact Tachometer

When using a non contact tachometer, it is vital to understand its main components:

- Laser/Light Source: Generates the signal that will reflect off the surface of the rotating object.

- Receiver: Captures the reflected signal and converts it into readable data.

- Display: Shows the measured speed in RPM (Revolutions Per Minute) or other relevant units.

Preparations for Using a Non Contact Tachometer

To ensure optimal performance, follow these preparations:

- Make sure the object's surface is clean and reflective.

- If using an optical tachometer, affix a reflective tape at an easily visible point on the rotating object.

- Choose an appropriate distance between the sensor and the objectthis varies depending on the model.

Step-by-Step Guide on How to Use Non Contact Tachometer

Step 1: Set Up the Device

Position the non contact tachometer at the right distance from the object you want to measure. Make sure it is stable and secure.

Step 2: Power On the Tachometer

After positioning, power on the device. Ensure its calibrated, especially if it's a new unit or hasnt been used for some time.

Step 3: Aim at the Target

Carefully aim the tachometer's laser or light beam at the reflective surface of the rotating object. This action is crucial as it ensures accurate readings.

Step 4: Take the Measurement

Press the button to initiate the measurement. The tachometer will usually display the RPM after a few moments. Make sure to hold the device steady during this time for the most accurate results.

Common Applications of Non Contact Tachometers

Non contact tachometers are used in various fields, such as:

- Manufacturing: To monitor machinery and ensure smooth operations.

- Automotive: To assess engine speeds and other mechanical functions.

- HVAC systems: To validate the operational speed of fans and motors.

Safety Precautions When Using Non Contact Tachometers

While using a non contact tachometer, consider the following safety precautions:

- Do not aim the laser at anyone's eyes.

- Ensure all applicable electrical safety measures are in place.

- Be mindful of the environment; avoid using the device in areas with excessive dust or moisture.

Maintenance Tips for Non Contact Tachometers

To prolong the lifespan of your device and ensure optimal performance:

- Keep the lens clean and clear of obstructions.

- Store the device in a dry place when not in use.

- Regularly check for any signs of wear or damage to the unit.

Frequently Asked Questions

1. What is the range of a non contact tachometer?

The operational range varies by model, but many can measure speeds from a few RPMs up to tens of thousands.

2. Can I use a non contact tachometer in different industries?

Yes, non contact tachometers can be employed in various industries, including automotive, HVAC, and manufacturing.

3. What should I do if my tachometer shows inconsistent readings?

Inconsistent readings might suggest a dirty lens or improper positioning. Clean the lens and re-align the device before taking more measurements.

For further insights into tachometers, check out this AZO Sensors article.

In conclusion, mastering how to use a non contact tachometer is invaluable for tech enthusiasts and professionals alike. The precision and versatility offered by these devices can significantly enhance your work, helping you achieve accurate measurements effortlessly. Whether troubleshooting machinery, optimizing performance, or satisfying your curiosity, these tools are essential in the toolbox of anyone dealing with rotational speeds.