How to Ensure Car Paint Quality with Automated Inspection Systems?

Share

In the fast-evolving world of automotive manufacturing, the quest for top-notch quality is relentless. One of the defining attributes of a vehicle comes down to its exterior finish, and this is where ensuring car paint quality with automated inspection systems plays an essential role. With advancements in technology, car manufacturers now rely on intricate systems to maintain the aesthetic and functional standards of their paint jobs. An apparent upgrade from conventional methods, these automated inspection systems promise efficiency and precision.

In particular, as the automotive industry embraces innovation, tech professionals and enthusiasts alike must grasp the pivotal transformations occurring in car paint inspection. Understanding the intricacies of such systems not only enhances knowledge but prepares industry players to tackle the challenges of maintaining quality in a highly competitive market.

The Need for Quality in Car Paint

Quality car paint does not just add to the vehicle's appearance; it also plays a crucial role in protecting against environmental factors. High-quality paint jobs enable surfaces to withstand UV damage, corrosion, and scratches. For manufacturers, ensuring uncompromised paint quality is non-negotiable because:

- Brand Reputation: A flawless paint job reflects positively on the brand.

- Customer Satisfaction: Customers expect their vehicles to look pristine, influencing their purchase decisions.

- Longevity: High-quality paint applications contribute to the longevity of the car.

Understanding Automated Inspection Systems

Automated inspection systems leverage advanced technologies to evaluate the car paint process. These systems utilize a combination of software and hardware to accurately detect defects, ensuring that the paint applied is of exceptional quality. Key elements of an automated inspection system include:

- Vision Systems: High-resolution cameras scan the surfaces for flaws.

- AI and Machine Learning: These technologies analyze data and identify patterns in defects.

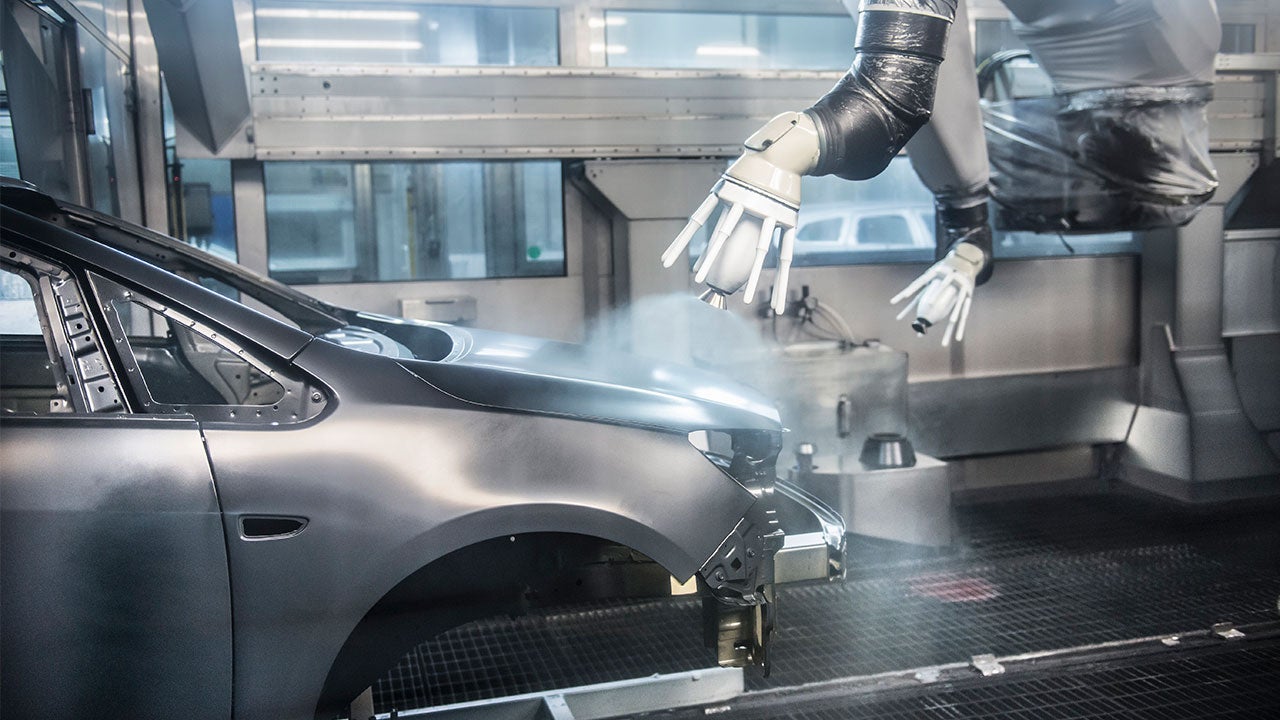

- Robotic Integration: Automated systems often incorporate robotic arms, facilitating precision in eliminating paint defects.

Through the integration of these technologies, manufacturers can achieve goals set by industry standards. Relevant insights can be gained by reading more on how eliminate paint defects to enhance quality further.

The Process of Automated Paint Inspection

The process of ensuring car paint quality begins with preparation and post-application inspection. Here is a typical workflow:

- Preparation: Surface scanning begins before paint application to ensure the area is free from blemishes.

- Paint Application: The application of paint is typically done using robots to maintain consistency.

- Post-Application Inspection: After paint application, the automated systems perform a thorough inspection.

- Analysis: Data from inspections are analyzed and compared against acceptable quality metrics.

Benefits of Using Automated Inspection in Car Paint Quality

The shift towards automated inspection brings a plethora of benefits:

- Speed: Automation drastically reduces inspection times compared to manual evaluation.

- Accuracy: These systems minimize human error, providing more reliable quality control.

- Consistency: Every vehicle undergoes a uniform inspection process, leading to standardization in quality.

- Data Collection: Automated systems gather and store data, facilitating ongoing quality assessments and continuous improvement.

Challenges of Automated Paint Inspection Systems

While automated inspection systems promise many advantages, they come with challenges. Some of the most significant include:

- Cost: Initial investment and maintenance costs can be high.

- Technical Skills: The need for skilled operators to manage and maintain sophisticated systems.

- System Calibration: Regular calibration is necessary to maintain inspection accuracy.

For further insights on overcoming these challenges, consider reading about overcoming challenges.

Future Trends in Car Paint Inspection

The automotive paint inspection technology is rapidly evolving, with trends that suggest exciting advancements:

- Integration with IoT: The Internet of Things (IoT) will allow for remote monitoring and real-time updates.

- Increased Use of AI: More sophisticated AI algorithms will enhance defect detection capabilities.

- Augmented Reality: AR could be utilized for visualizing defects and guiding manual repairs when necessary.

Conclusion

Ensuring car paint quality with automated inspection systems is more than a trend; it is becoming a pivotal aspect of modern automotive manufacturing. For tech professionals and enthusiasts, understanding these systems equips individuals with the knowledge necessary to navigate the evolving landscape of car production. For further reading on how to boost car paint quality with these technologies, check out this link: boost car paint quality.

Frequently Asked Questions

What are automated inspection systems?

Automated inspection systems utilize technologies like sensors, cameras, and AI algorithms to evaluate products' quality and detect defects during the manufacturing process.

How do these systems improve paint quality?

They minimize human error, provide consistent assessments, and gather valuable data to track quality over time.

Are automated inspection systems cost-effective?

While they require a significant initial investment, the long-term savings from improved efficiency and reduced defects often justify the costs.