How to Install Aftermarket Tachometer: A Terrific Guide

Share

Installing an aftermarket tachometer can be a life-changing upgrade for any automotive enthusiast or tech professional. Whether youre looking to monitor your engine's performance or just enjoy the visually appealing design of an aftermarket unit, knowing how to install an aftermarket tachometer properly makes all the difference. This comprehensive guide will walk you through each step of the installation process in a detailed yet engaging manner.

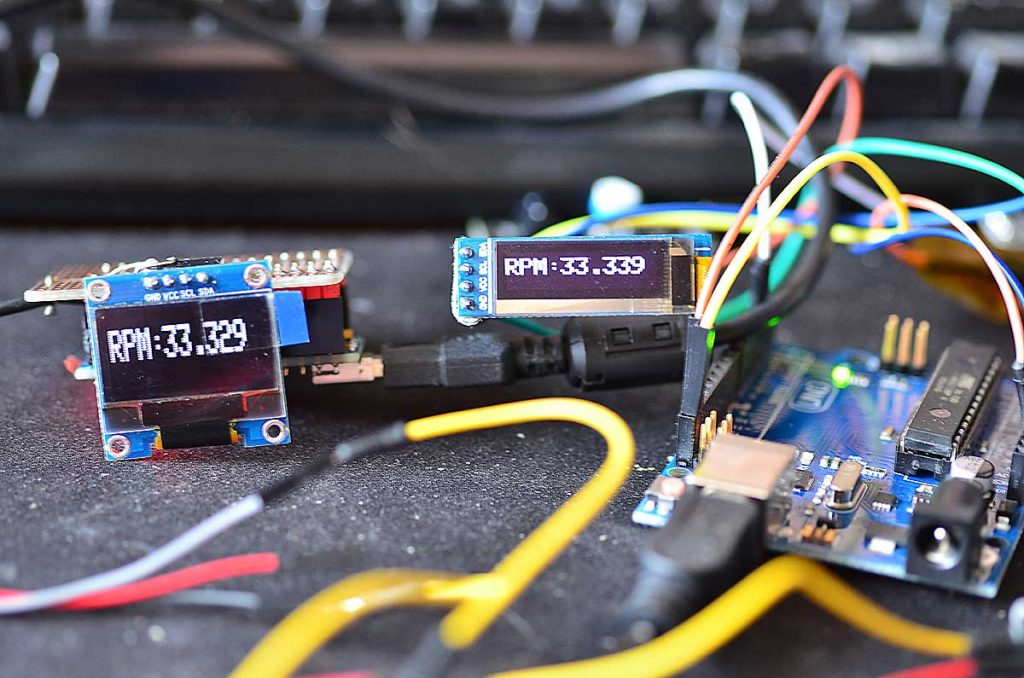

Before diving into the specifics, lets define what a tachometer is. A tachometer is a device that measures the rotational speed of an engine. Having accurate readings from your tachometer can significantly improve your driving experience. If you're eager to learn how to install an aftermarket tachometer, youve come to the right place!

Understanding the Basics

Before jumping into the installation, its crucial to understand the core components of a tachometer and how they function. The aftermarket tachometers are available in various models, including analog and digital units. Each type offers different features and encasing options which can influence your decision. You can find more detailed information on various types of tachometers.

The Tools You'll Need

To ensure a smooth installation process, gather the following tools:

- Normally, a screwdriver set

- Wire strippers

- Heat shrink tubing or electrical tape

- A socket set

- Drill and drill bits

- Multimeter to check wiring

Choosing the Right Location for Installation

Your first step in how to install aftermarket tachometer is to select an appropriate installation location. The location you choose should be visible without obstructing your view of the road. Most enthusiasts prefer the dashboard, as it allows for easy monitoring without distraction.

Ensure that the location you choose adheres to safety regulations in your area. If you're unsure about what those regulations entail, checking local laws may be a good idea.

Wiring the Tachometer

One of the most critical aspects of installation is wiring. The tachometer relies on a few main wires to receive power and communicate with your vehicle's engine management system. Heres a simplified outline of what to do:

- Power Supply: Connect the red wire (usually for power) to the ignition switch or a direct battery terminal.

- Grounding: The black wire needs to be connected to a good chassis ground.

- Signal Wire: The green wire typically connects to the ignition coil or directly to the spark plug wire. This wire is vital as it sends RPM data to the tachometer.

For further understanding, check out how tachometers work.

Mounting the Tachometer

Once you've completed the wiring process, its time to mount your tachometer securely. Depending on the model chosen, your installation kit may include brackets or screws. Use the drill to create fastening holes if necessary. Make sure everything is properly tightened; you wouldnt want a wobbling tachometer distracting you while driving.

Prior to finalizing the installation, take a step back and ensure that the angle and visibility are optimal. You want the tachometer to complement your vehicles aesthetics while providing accurate readings.

Testing the Installation

After installation, the work isnt quite done yet. Youll want to perform a test to ensure everything is functioning correctly. Start the vehicle and watch your tachometer carefully:

- If it rises smoothly in accordance to engine RPM, youre good to go.

- If the readings are erratic, double-check your wiring connectionsensure they are snug and correct.

For a reference on what a normal tachometer reading looks like, explore this detailed guide.

Common Issues Faced During Installation

Many tech enthusiasts encounter a few common issues while installing an aftermarket tachometer. Here are some of the problems and their solutions:

- Fluctuating Readings: If you notice the tachometers needle jumping around, it may be caused by poor grounding. Ensure a solid ground connection.

- No Readings: If your tachometer displays no readings at all, check the signal wire connections to the ignition coil.

- Interference: If the tachometer is adversely affected by electrical interference, consider adding ferrite beads to your wiring.

If you want to dive deeper into why tachometers fluctuate, check this informative article.

Maintenance Tips for Your Aftermarket Tachometer

Once your tachometer is successfully installed and operational, maintaining it is essential. Here are a few tips to keep it in top shape:

- Regularly inspect the wiring connections for any signs of corrosion or wear.

- Keep the glass clean to ensure visibility.

- If the readings seem off, recalibrate your tachometer following the manufacturer's instructions.

Conclusion

Installing an aftermarket tachometer can undoubtedly elevate your driving experience. Armed with this guide, you should be well-prepared to tackle the installation yourself. The knowledge you gain will not only make your vehicle more advanced but could also lead to improved performance and responsiveness.

Feel free to explore additional resources, such as red sections in tachometers, for a deeper understanding of this important automotive instrument.

FAQs

1. Can I install an aftermarket tachometer on my own?

Yes, with basic tools and some technical knowledge, you can install it yourself.

2. What if my car doesnt have a tachometer port?

You can still install one by using a signal wire from the ignition coil.

3. How often should I check my tachometers performance?

Its best to check it at regular intervals to ensure accurate readings.

Now that you understand the process and considerations for installing an aftermarket tachometer, its time to gather your tools and get started!