How to Test a Diesel Tachometer: Essential Guide for Pros?

Share

For many tech professionals and enthusiasts, understanding the intricacies of a diesel tachometer is crucial in maintaining optimal engine performance. Knowing how to test a diesel tachometer not only ensures that you monitor your engines RPM accurately but also prevents potential malfunction that could lead to costly repairs. This article walks you through comprehensive steps to effectively test your diesel tachometer.

The diesel tachometer is an essential instrument that measures the rotational speed of the engine's crankshaft. It provides vital information, helping you gauge engine performance, efficiency, and overall health. With the right knowledge and tools, testing your tachometer can be a straightforward task. Lets break it down step by step.

Understanding the Basics of Your Diesel Tachometer

Before diving into the testing process, it is essential to familiarize yourself with the components of your diesel tachometer. Typically, a diesel tachometer will consist of several key parts:

- Input Signal Source: This can be a magnetic pickup or a signal from the engine's electronic control unit.

- Calibration Settings: Many modern tachometers come equipped with adjustable settings to ensure accurate readings.

- Display: The visual representation of RPM, which can be analog or digital.

Understanding these components will help you troubleshoot any issues during testing.

Required Tools for Testing

To effectively test your diesel tachometer, you'll need a few essential tools:

- Digital Multimeter: This device will help you check electrical outputs.

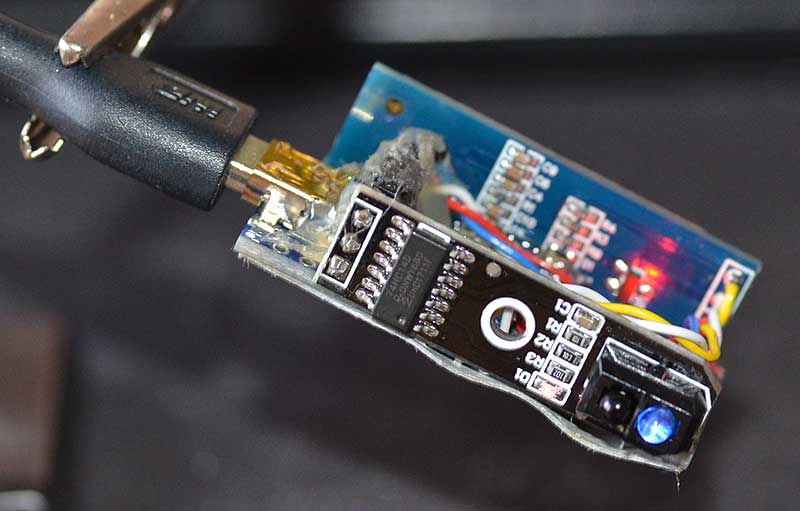

- Oscilloscope: Useful for examining waveforms if you are looking into more intricate issues.

- Wiring Diagrams: Ensure you have the correct diagrams for your specific vehicle model.

- Tachometer Tester: This specialized tool can simulate input signals to check the tachometer's response.

Steps to Test a Diesel Tachometer

Step 1: Preliminary Checks

Start with visual inspections of your diesel tachometer and its connections. Check for:

- Worn or frayed wires

- Loose connections

- Corrosion at terminals

If any issues are spotted, address them before proceeding to the next steps.

Step 2: Voltage Check

The next phase involves using your digital multimeter to check for voltage. Heres how:

- Set your multimeter to the voltage setting (DC).

- Connect the black probe to the ground and the red probe to the tachometers input wire.

- Start the engine and observe the reading. A steady voltage indicates that the tachometer should function properly.

For more details on broader tachometer functionalities, you can visit Science Direct.

Step 3: Signal Testing

Now it's time to check the signal generated by the engine:

- Use an oscilloscope to monitor the signal.

- Attach the oscilloscope probe to the tachometer signal wire.

- Crank the engine and observe the waveform. A clear, consistent waveform should signify that the tachometer is receiving adequate signals.

Step 4: Testing with a Tachometer Tester

If available, a tachometer tester can provide definitive diagnostics. To use it:

- Connect the tester to the tachometer following the manufacturer instructions.

- Simulate different RPM inputs and check the tachometers response.

The tachometer should accurately display the RPM provided by the tester.

Additional Tips for Tech Enthusiasts

Testing a diesel tachometer can often reveal underlying issues that may not be immediately apparent. Here are some additional tips:

- Keep Your Software Updated: If you are using a digital tachometer, ensure that the engines software is up-to-date.

- Regular Maintenance: Perform consistent checks on the tachometer, especially after heavy usage.

- Utilize Forums and Communities: Engage with fellow tech enthusiasts to share insights and troubleshooting tips.

Conclusion

In conclusion, knowing how to test a diesel tachometer is a vital skill for any professional or enthusiast in the field of automotive technology. By following these outlined steps, you can ensure your tachometer is functioning correctly, enhancing overall engine performance. For more insights on how to adjust your tachometer, check out this link on tack adjustments or explore maintenance and repair tips.

Remember, a well-maintained tachometer can significantly impact engine longevity and efficiency.

FAQs

What is the purpose of a diesel tachometer?

A diesel tachometer measures the engine's rotational speed (RPM) and helps monitor performance, ensuring it runs efficiently.

How often should I test my diesel tachometer?

It is advisable to test your tachometer every 6 months or after significant maintenance tasks to ensure proper functionality.

What if my tachometer is not responding?

If your tachometer isnt responding, check for electrical issues, verify wiring connections, and test with a multimeter.