How to Test Tachometer Signal with Multimeter? Essential Guide

Share

Testing the tachometer signal with a multimeter is a crucial skill for any tech professional or enthusiast working with automotive engines and machinery. This article delves into the methods of testing tachometer signals, covering its workings, possible issues, and the essential steps to effectively utilize your multimeter.

The process of understanding how to test tachometer signal with multimeter requires a solid foundation in how tachometers operate, what signals they generate, and how to accurately measure those signals with a multimeter.

Understanding the Tachometer Function

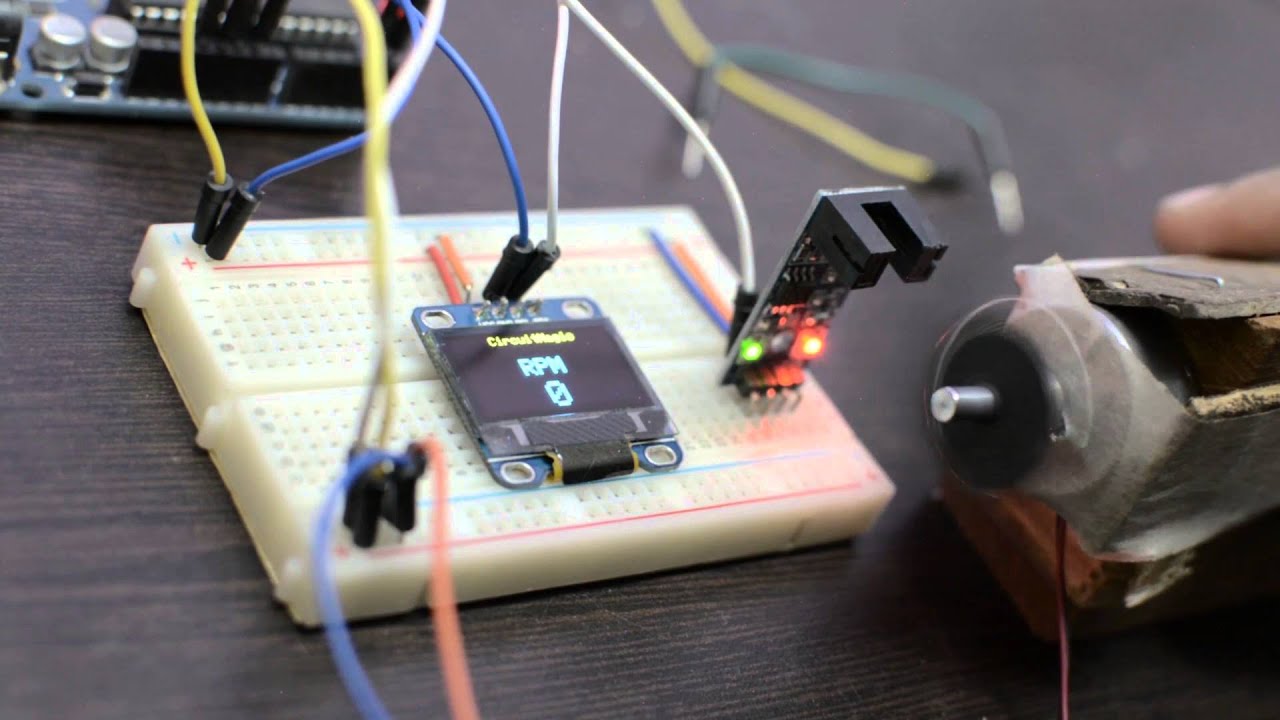

A tachometer is an instrument that measures the rotation speed of a shaft or disk, typically in revolutions per minute (RPM). It is widely used in automotive systems, industrial machinery, and aviation. The tachometer assists operators in gauging engine performance and efficiency. A malfunctioning tachometer can lead to serious issues including engine over-revving or inefficiency.

The Types of Tachometers

There are several types of tachometers, each operating based on different principles. These include mechanical, electronic, and digital tachometers. When testing the signal, it's essential to identify the type of tachometer you're dealing with.

- Mechanical Tachometers: Often found in older vehicles, they use a flexible shaft and rotational force to display RPM.

- Electronic Tachometers: These utilize electrical signals from the engine to determine RPM, generally having more accuracy and reliability.

- Digital Tachometers: A modern iteration that showcases rotational speed in a digital format. They often have advanced features like memory and programming.

How Does a Tachometer Generate a Signal?

Tachometers generate signals based on the rotational motion of the engine or machinery. The sensor linked to the tachometer translates the spinning motion into electrical signals. Common sensors used are:

- Inductive Sensors: Create a voltage pulse as they detect the movement of a metal component.

- Hall Effect Sensors: Use magnetic fields to produce a voltage change indicating RPM.

- Optical Sensors: Utilize light pulses to measure the rate of rotation.

Common Issues with Tachometers

Understanding typical tachometer problems can aid in troubleshooting and testing. These include:

- Fluctuating readings: This could stem from signal interference or poor electrical connections. For more details on this topic, read about cause of fluctuations.

- Inaccurate readings: These can indicate sensor issues or wiring problems.

- The red section of the tachometer: This indicates dangerous RPM levels, affecting engine performance. Learn more about the red section.

Equipment Needed for Testing

Before diving into the testing process, gather the following equipment:

- Multimeter: Capable of reading voltage, resistance, and frequency.

- Wiring Diagrams: Essential for understanding circuit connections.

- Safety Gear: Such as gloves and goggles for protection during testing.

Steps for Testing Tachometer Signal with a Multimeter

Follow these structured steps to effectively test the tachometer signal using a multimeter:

- Safety First: Always disconnect the vehicles battery before starting any work.

- Identify the Tachometer Wires: Reference your wiring diagrams to locate the input and output wires of the tachometer.

- Set Multimeter to DC Voltage: This is typically the mode needed for tachometers, especially in automotive applications.

- Connect Multimeter: Attach the black probe to a good ground and the red probe to the tachometer signal wire.

- Have Someone Rev the Engine: Observe the changes in the multimeter reading as RPMs increase. It should correlate with the engine speed.

- Check Voltage Levels: Document the readings and compare them to vehicle specifications.

Common Multimeter Readings

Understanding various voltage levels while running the tachometer helps in diagnosing problems:

- 0-12V: Indicates idle RPMs and low signal strength.

- 9-12V: Normal operating range (consult your vehicle specifications).

- Below 9V: Potential issues within the tachometer system.

What If the Signal is Inconsistent?

Inconsistent readings require immediate troubleshooting, which may involve checking:

- Connections: Look for loose or corroded connectors.

- Sensor: Test the sensor output to confirm it generates the correct signal.

- Wiring: Inspect for damaged wires that may cause disruption in signal transmission.

Advanced Testing Techniques

For experienced users, utilizing an oscilloscope can provide deeper insights into the tachometer signal. This tool can illustrate the waveforms, indicating any signal distortion or anomalies.

Additionally, learn more about what sensors control the tachometer and their effectiveness by reading about sensor controls.

Conclusion

Tachometer testing using a multimeter is a valuable skill for tech professionals and enthusiasts alike, ensuring accuracy in engine performance monitoring. By following these steps, understanding the nuances of tachometer operation, and adhering to safety protocols, you will be well-equipped to handle most tachometer-related issues.

FAQs

-

1. How often should I test my tachometer?

Its wise to perform periodic checks, especially if you notice your RPMs fluctuating or the tachometer acting erratic. -

2. What are the signs of a faulty tachometer?

Inaccurate readings, particularly frequent fluctuations or readings at zero, typically indicate issues. -

3. Can I test the tachometer signal while the engine is running?

Yes, but it requires careful handling and ensuring proper connections to avoid electrical shorts.

By becoming proficient in how to test tachometer signal with multimeter, you empower your skills in automotive diagnostics and maintenance.

For in-depth knowledge about normal tachometer readings, check out normal readings.