How to Wire a VDO Tachometer for Accurate Readings?

Share

When it comes to enhancing your automotive experience, understanding how to wire a VDO tachometer can significantly elevate your gauge game. A tachometer is an essential device that provides engine speed data, and for tech professionals and automotive enthusiasts, wiring one correctly ensures you receive accurate metrics to enhance performance. In this article, we will walk you through the entire process, step by step, while addressing common challenges faced during the installation.

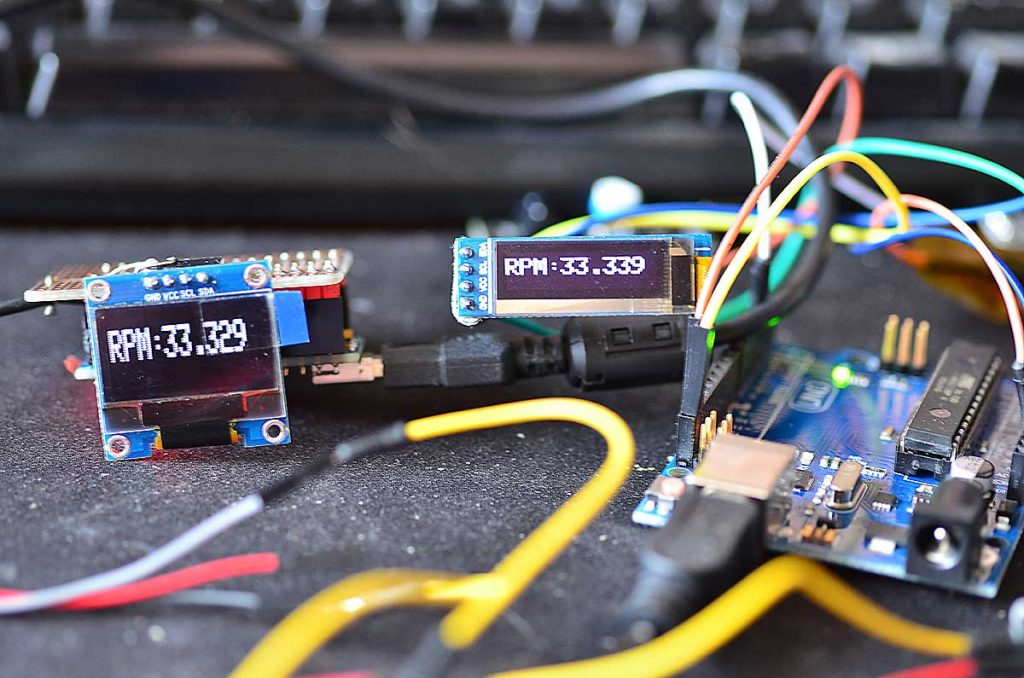

Before diving into the specifics of wiring, its vital to grasp the basics of a tachometer and its purpose. Typically, a tachometer measures the engine's RPM (revolutions per minute), allowing you to monitor engine speed accurately. This information is critical, especially when you're pushing your vehicle to its limits, facilitating smoother shifts and avoiding potential engine damage. Lets dive right into the wiring process!

Understanding the Components of a VDO Tachometer

Understanding the components involved is the first step in mastering how to wire a VDO tachometer. The primary elements include:

- Tachometer gauge

- Power source

- Signal wire (from the ignition coil)

- Ground wire

- Battery or alternative power supply

Having these components prepared helps streamline the wiring process. The **VDO tachometer** typically consists of a dial, a needle to indicate RPM, and wiring harnesses to connect to the vehicle's electrical system.

Gathering the Necessary Tools

Before starting the wiring process, ensure you have the following tools available:

- Wire strippers

- Screwdrivers

- Multimeter

- Electrical tape

- Wrenches

These tools will aid significantly in simplifying the wiring setup and ensuring secure connections.

Steps to Wire a VDO Tachometer

Now that you have the components and tools ready, lets get to the exciting part the actual wiring! Follow these steps meticulously to ensure a successful installation:

1. Disconnect the Battery: Always start by disconnecting the battery to avoid any accidental shocks or shorts during installation.

2. Locate the Ignition Coil: The signal wire from the tachometer connects to the ignition coil, which sends out the RPM signals. Refer to your vehicles wiring diagram to find the correct wire.

3. Connect the Signal Wire: Take the signal wire from the tachometer and connect it to the negative terminal of the ignition coil. This wire can be identified typically by its color (often green or orange). Its essential for receiving accurate RPM readings.

4. Power and Ground Connections: Connect the power wire from the tachometer to a switched power source - usually an accessory circuit that provides power when the ignition is on. Additionally, run the ground wire to a solid ground point on the vehicles chassis.

5. Installing the Tachometer: Mount the tachometer in the dashboard or another suitable position where you can easily view it while driving. Ensure the gauge is securely fastened.

6. Reconnect the Battery: Once all connections are made, reconnect the battery. Double-check all connections for any signs of shorts or loose wires.

7. Test the Installation: Start the vehicle and observe if the tachometer functions correctly. Rev up the engine and ensure the reading on the tachometer reflects the actual RPM.

Troubleshooting Common Issues

While you might follow all the steps accurately, you may still encounter issues. Here are common problems and how to resolve them:

- Tachometer not working: Check to see if there is a loose connection at the ignition coil or the tachometer itself.

- Inaccurate readings: Verify that the signal wire is attached correctly and that you have the right power source connected. Additionally, consult your vehicle's manual regarding tachometer compatibility.

- Interference: If youre experiencing needle bounce or erratic readings, it might be due to interference from other electronic devices. Ensure all wiring is well-shielded.

Benefits of Using a VDO Tachometer

Installing a VDO tachometer in your vehicle comes with several advantages:

- Enhanced Control: Provides real-time feedback on engine speed, helping with optimal shift timing and performance.

- Performance Monitoring: Enables tracking of engine performance and tuning adjustments based on RPM readings.

- Improved Safety: Avoid potential engine damage caused by over-revving by staying within optimal RPM ranges.

The Importance of Monitoring RPM

Monitoring RPM is not just a technical preference; its about safeguarding your engines longevity and performance. An accurate tachometer reading allows tech enthusiasts to fine-tune performance settings tailored to their driving style and needs.

For an in-depth understanding of tachometers, check out this Wikipedia page for a historical perspective.

Related Resources

For those interested in diving deeper into tachometers, the following resources may be beneficial:

FAQs

Q: Can I install a VDO tachometer in all vehicles?

A: While many vehicles support a VDO tachometer, always check compatibility with your specific model.

Q: What do I do if my tachometer needle is stuck?

A: Inspect for any physical obstructions or wiring issues that may cause the needle to remain stationary.

Q: How can I calibrate my tachometer?

A: Calibration typically involves following instructions provided by the manufacturer, often referring to the RPM at a certain speed.

In conclusion, knowing how to wire a VDO tachometer greatly enhances not just your vehicle's functionality but also your driving experience. Through precise readings, you can customize your driving style, improve engine efficiency, and maintain optimal performance. For a deeper understanding of tachometers, consider reading What Is a Tachometer?.