What is a Tachometer? Understanding Its Importance

Share

A tachometer is a crucial device in various industries and fields, providing insight into the rotational speed of an object. For tech professionals and enthusiasts, grasping the concept of tachometers is essential for comprehending their application in automotive engines, manufacturing machinery, and more. But what exactly is a tachometer, and why is it significant?

In simplest terms, a tachometer is an instrument that measures the rotational speed of a shaft or disk, typically in revolutions per minute (RPM). This measurement is vital for the effective operation of engines and mechanical systems, ensuring they function within optimal speed limits. Whether you are a seasoned engineer or a tech-savvy individual, understanding the intricacies of tachometers can provide valuable insights into technology and engineering.

Types of Tachometers

The tachometer comes in several forms, each suited for different applications. Heres a closer look at the primary types:

1. Analog Tachometers

Analog tachometers use a needle dial display to indicate RPM. They provide immediate feedback to the operator and are commonly found in older vehicles and equipment. Their straightforward nature makes them easy to interpret on the fly.

2. Digital Tachometers

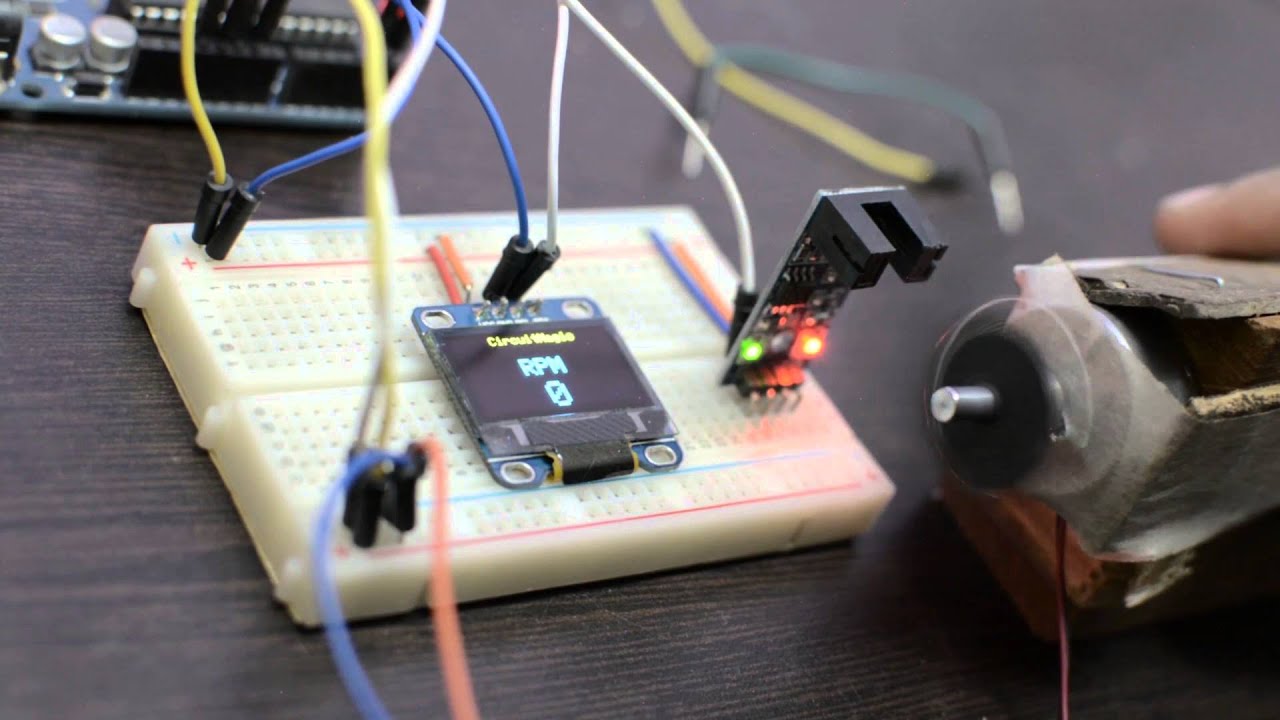

Digital tachometers present RPM readings in a numerical format on an electronic display. They are becoming increasingly popular due to their precision and additional features, such as data logging and integration with computer systems.

3. Contact and Non-contact Tachometers

Contact tachometers require physical contact with the rotating part to measure speed, while non-contact tachometers use laser or infrared technology to measure RPM from a distance. Non-contact types are particularly beneficial in hazardous environments.

4. Optical Tachometers

Optical tachometers utilize light sensors to measure the speed of rotating surfaces. This sensor detects the passage of reflective markers affixed to the spinning object, allowing for precise measurements.

How a Tachometer Works

Understanding the functionality of a tachometer requires a grasp of the underlying principles that govern its operation. Typically, a tachometer works by generating a signal as a result of the rotational motion it measures.

For instance, in an analog tachometer, a magnet attached to the rotating shaft induces a current in a coil wrapped around the magnet. As the shaft spins, the frequency of the induced current correlates with its speed. This information then drives the needle on the dial display, indicating the RPM.

In digital versions, sensors or encoders track the rotation speed and convert that data into a readable format, ready for output on an LCD screen. For a more in-depth explanation of tachometer functionality, visit How Does a Tachometer Work?.

The Importance of Tachometers in Modern Technology

In the realm of technology, tachometers play a vital role in ensuring systems operate efficiently. Here are some critical areas where tachometers are indispensable:

1. Automotive Engineering

In cars, tachometers help drivers optimize engine performance. By monitoring RPM, drivers can make informed decisions about gear shifts, thereby enhancing fuel efficiency and reducing wear on engine components.

2. Industrial Applications

Tachometers are widely used in manufacturing processes to monitor equipment performance. Precise RPM measurements help maintain product quality and mitigate equipment failure, making them crucial tools in industry.

3. Aerospace Engineering

In aviation, tachometers are essential for monitoring aircraft engine performance. Accurate RPM readings allow pilots to make adjustments crucial for safety and efficiency during flight.

Applications of Tachometers

The uses of tachometers extend beyond mere RPM measurement. Many advanced tachometers are integrated into control systems to help maintain performance under varying conditions.

For example, in robotics and automation, tachometers help monitor motor speeds in real-time, providing feedback necessary for precise control in automated processes. Their application in these fields demonstrates their versatility and adaptability in the technology landscape.

Future Developments and Innovations

As technology advances, the capabilities of tachometers will continue to evolve. Innovations such as wireless connections and enhanced data analytics are transforming how tachometers function and the data they provide.

Moreover, new materials and more efficient sensors are set to enhance accuracy while reducing size and cost. Keeping an eye on these developments will be beneficial for tech professionals looking to stay at the forefront of industry advancements.

Frequently Asked Questions (FAQs)

1. What is the primary function of a tachometer?

The primary function of a tachometer is to measure and display the rotational speed of a shaft or disk, usually in revolutions per minute (RPM).

2. How accurate are tachometers?

Most tachometers provide accurate readings within a minimal margin of error, typically around 1% or less, depending on the design and quality of the device.

3. Can tachometers be used for purposes other than automotive?

Yes, tachometers have applications in various fields including manufacturing, aerospace, and robotics, where monitoring speed is critical for performance and safety.

For more information on related devices like stroboscopes, check out What is a Stroboscope? to learn about its functionalities.

As an Amazon Associate, I earn from qualifying purchases.