What is Mechanical Tachometer and How Does it Work?

Share

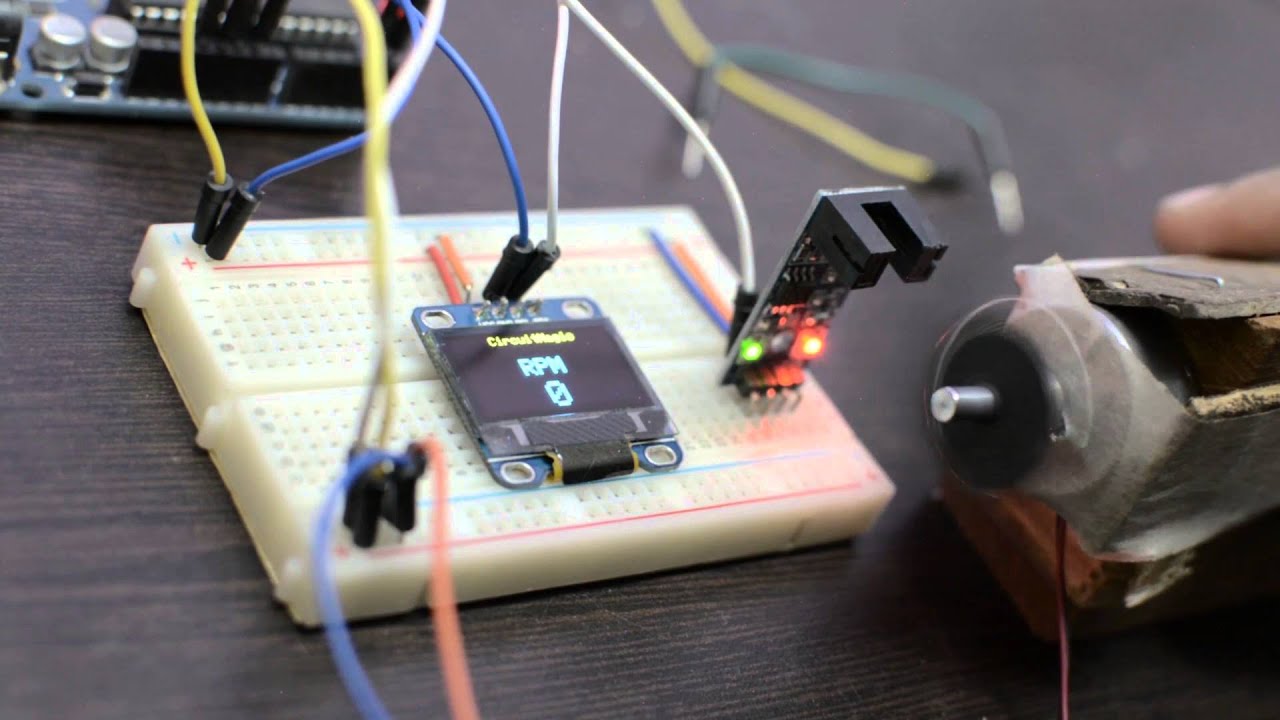

In the world of engineering and technology, the term 'what is mechanical tachometer' often comes up among professionals and tech enthusiasts. A tachometer is a device that measures the rotational speed of an object, typically in revolutions per minute (RPM). Understanding how it works can provide valuable insights for various applications, from automotive engineering to industrial machinery.

This article will cover everything you need to know about mechanical tachometers, their operation, types, application areas, and troubleshooting tips to know when they stop working. Lets dig into the fascinating world of tachometers!

The Basics of Tachometry

A tachometer is an essential instrument in many engineering applications. Its primary function is to measure the speed of rotation, and it can be either electronic or mechanical.

Mechanical tachometers are primarily known for their durability and reliability in various settings. They use mechanical means, often involving gears, to measure and display rotational speed. Their design makes them particularly suitable for environments where electronic devices may fail.

How Does a Mechanical Tachometer Work?

To understand 'what is mechanical tachometer', it's crucial to know how they work. Mechanical tachometers operate based on centrifugal force. As the shaft rotates, centrifugal force acts on a weight that moves against a spring. This movement will then translate to a reading on a dial or gauge.

As the speed increases, the centrifugal force overcomes the spring tension, causing the dial needle to move. The faster the shaft rotates, the further the needle moves, which indicates an increase in RPM. Many mechanical tachometers feature a red zone to indicate maximum safe operational speedsessential for preventing engine damage.

Types of Mechanical Tachometers

There are several variations of mechanical tachometers, including:

- Direct-reading tachometers: These provide a direct indication of speed and are commonly seen in vehicles.

- Indicating tachometers: They utilize a pointer and dial to show the speed of rotation.

- Integrating tachometers: These are more complex devices capable of calculating additional parameters over time.

Applications of Mechanical Tachometers

The applications of mechanical tachometers span various industries, including:

- Automotive engineering: They are used to monitor engine speeds in vehicles.

- Industrial machinery: Essential in controlling the performance of motors and turbines.

- Marine engineering: Used in boats to keep track of engine RPMs for optimal performance.

Benefits of Mechanical Tachometers

Mechanical tachometers offer several advantages:

- Durability: They are designed to withstand tough conditions without failing.

- No power requirement: Unlike electronic tachometers, mechanical versions do not depend on external power sources.

- Simplicity: Their straightforward design makes them easy to read and interpret.

Troubleshooting Mechanical Tachometers

Understanding 'what is mechanical tachometer' also involves knowing how to troubleshoot potential issues. Common problems include:

- Incorrect readings: This can occur if the cables are faulty or if there is a mechanical failure within the device. Check connections and gauge movement.

- Complete failure: If the tachometer does not respond at all, inspect the mechanism for blockage or breakdown.

- Fluctuating readings: This issue could result from vibrations or a loose connection that needs tightening.

For more detailed troubleshooting tips, check out this link about tachometers stopping working.

Frequently Asked Questions (FAQs)

What is the difference between mechanical and electronic tachometers?

While both devices measure rotational speed, mechanical tachometers use physical components, whereas electronic tachometers rely on electronic signals.

How can I test a mechanical tachometer?

Testing can be conducted using a multimeter or another tachometer to compare readings.

Where are mechanical tachometers commonly used?

They are prevalent in automotive, industrial, and marine applications where speed measurement is critical.

For further information about the workings of tachometers, refer to this informative blog.

In summary, understanding 'what is mechanical tachometer' is vital for professionals in various industries. This device not only provides essential data but also contributes to the safety and efficiency of machinery operations.