Connecting a Tachometer to a Summit Ready to Run Distributor

Share

When you're working on automotive electronics, understanding how to hook tachometer to summit ready to run distributor is essential. A correctly functioning tachometer gives you vital information about your engine's revolutions per minute (RPM), allowing you to monitor engine performance and shifts effectively. This article provides a detailed guide aimed at tech professionals and enthusiasts who want to excel in vehicle modifications and enhancements.

What You Need Before Getting Started

Before diving into the connections and installations, it's important to gather all necessary components. Heres what you need:

- Tachometer: Ensure that your tachometer is compatible with your engine setup.

- Summit Ready to Run Distributor: This distributor offers excellent ignition timing and reliability.

- Wire Connectors: Use high-quality connectors to ensure solid electrical connections.

- Tools: Have a screwdriver, wire stripper, and multimeter ready.

Understanding the Basics of a Tachometer

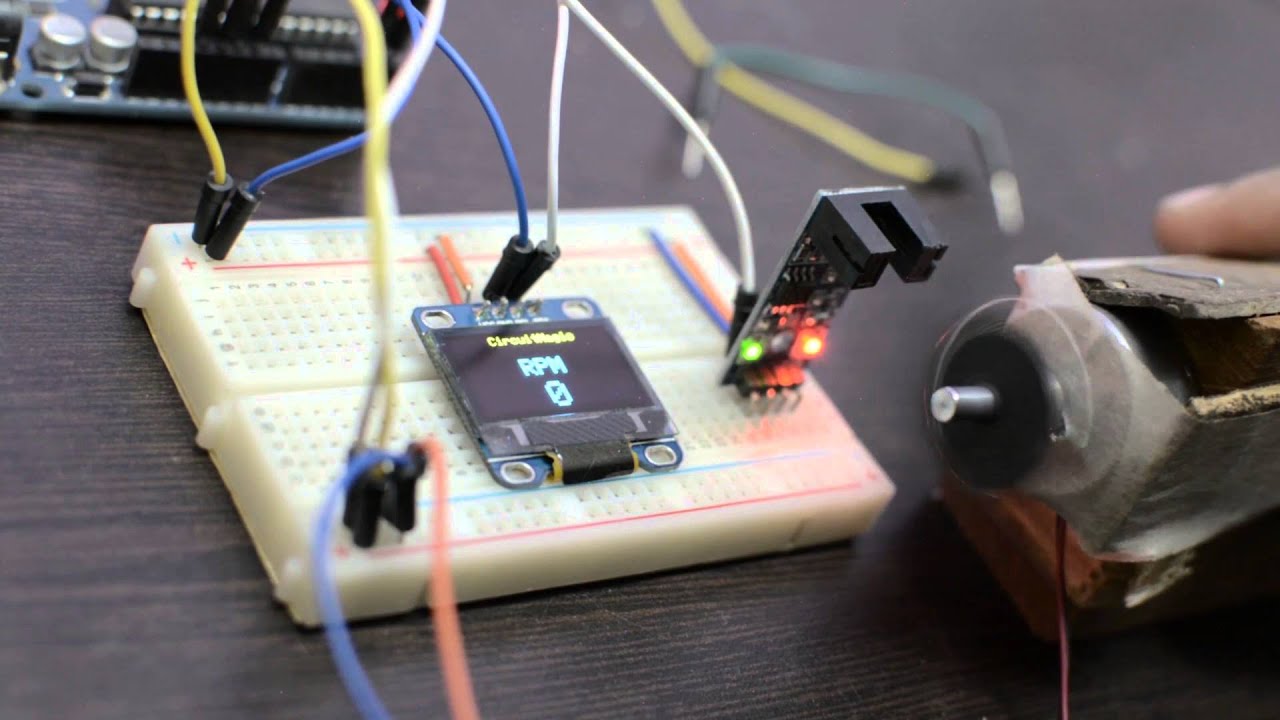

A tachometer is a device used to measure the rotational speed of a shaft or disk. For automotive applications, it provides real-time RPM readings from the engine. Learn more about what a tachometer is and its significance in your vehicle.

Step-by-Step Guide to Connect the Tachometer

Step 1: Prepare Your Setup

Ensure that both the tachometer and the distributor are isolated from power. Disconnect the battery terminals to avoid electrical shocks. This is a crucial step to guarantee safety while handling electrical components.

Step 2: Identify Your Wires

Locate the wire harness attached to the Summit Ready to Run Distributor. The tachometer typically receives a signal from the ignition coil or the distributor. Based on your specific wiring diagram, identify the correct wire:

- Negative Terminal of the Coil: This is the most common location for tachometer connections.

- Distributor Output: Alternatively, you might connect the tachometer to the distributors output terminal.

Step 3: Connect the Wires

Once you have identified the correct connection point, it's time to hook things up:

- Attach the tachometer wire to the negative terminal of the ignition coil or to the designated terminal on the distributor.

- Use high-quality connectors to ensure a solid connection.

- Double-check all connections to ensure there are no loose wires.

Step 4: Final Setup

Now that your tachometer is connected, you can reattach your battery terminals. Make sure to securely tighten them.

Testing the Connection

After wiring, the next step is to test the connection:

- Start the engine and observe the tachometer. It should register the RPM.

- Rev the engine slightly; the tachometer should respond accordingly.

- If the tachometer does not register, double-check your wiring and connections.

Common Issues and Troubleshooting

Sometimes, issues may arise when connecting the tachometer. Here are some common problems and solutions:

- No reading on the tachometer: This may occur due to a loose connection. Ensure all connections are tight.

- Erratic readings: This could be caused by interference. Make sure to route the wiring away from high voltage sources.

- Incompatible tachometer: Some older tachometers may not work with modern distributions. Check compatibility before purchasing.

Further Reading and Learning

If you're looking for more information on the functioning of tachometers or their applications, consider reading this article on mechanical tachometers or how to test a tachometer.

Frequently Asked Questions

1. Can I use any tachometer with my Summit Distributor?

No, you need to ensure that the tachometer is compatible with your specific distributor model for accurate readings.

2. What if my tachometer is not responsive?

Check your connections and ensure that the tachometer is receiving power and a signal from the ignition system.

3. Is it necessary to use a specific wire gauge for connections?

Yes, using an appropriate wire gauge will prevent voltage drops and electrical interference.