How to Use a Tachometer on a Centrifuge Effectively?

Share

In the realm of **centrifugation**, understanding the mechanics behind measurement tools is essential for tech professionals and enthusiasts. One such tool is the **tachometer**, which plays a crucial role in determining the rotational speed of the centrifuge. This article aims to provide an in-depth yet **engaging** guide on how to use a tachometer on a centrifuge, enabling you to optimize performance and ensure precise results.

The primary function of a tachometer is to measure the rotational speed, usually in revolutions per minute (RPM). Knowing how to use this instrument effectively can greatly impact your work. So, how can you utilize this tool efficiently on your centrifuge? Lets dive into the details.

What is a Tachometer?

A tachometer is an instrument designed to measure the rotation speed of an object, providing critical insights into performance metrics. In a centrifuge, this is especially important, as precise speed control can affect the outcome of laboratory tests and experiments. For additional insights, check out this article on how a tachometer works.

Why Use a Tachometer on a Centrifuge?

Utilizing a tachometer on a centrifuge ensures that you are running your device at the correct speeds suitable for your application. This is vital for separating substances based on density and other characteristics. Check out information on tachometer basics to further understand its importance.

Types of Tachometers

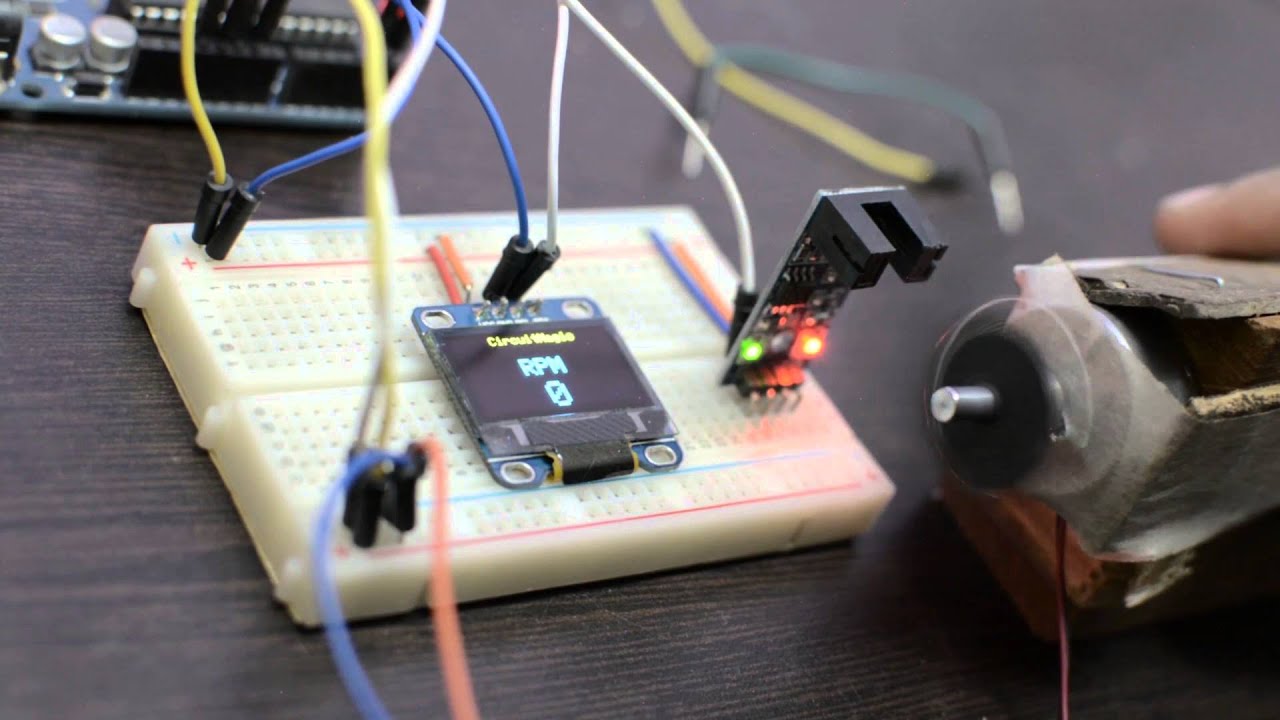

There are two main types of tachometers: **contact** and **non-contact**. Understanding these can help you choose the best option for your centrifuge applications.

Contact Tachometers

These devices touch the spinning part of the centrifuge to measure speed directly. They are typically more accurate but may introduce wear over time or require maintenance. If you are insightful about how contact tachometers work, read more on it at this link.

Non-Contact Tachometers

Utilizing lasers or light reflection, non-contact types provide readings without physical interaction. They reduce wear and tear, making them ideal for sensitive equipment like centrifuges. To learn more about how to use non-contact tachometers, refer to the aforementioned link.

Steps to Use a Tachometer on a Centrifuge

Using a tachometer on your centrifuge may seem daunting, but by following these steps, you can quickly get familiar with the process:

Step 1: Prepare the Equipment

Before operation, ensure that your **centrifuge** is properly set up. Double-check that all components are working effectively.

Step 2: Understand the Specifications

Familiarize yourself with your centrifuge's specifications, including maximum speed and type of rotor you'll be using.

Step 3: Setting Up the Tachometer

If you are using a contact tachometer, attach it to the relevant part of the centrifuge following manufacturer instructions. For non-contact variants, position it according to the manual so it can read accurately without interference.

Step 4: Measuring RPM

Once set up, turn on your centrifuge. Watch the tachometer as it displays the RPM. Make sure to take note of critical speed characteristics for your application.

Step 5: Document Your Findings

Keep a record of the speeds you reached and any anomalies observed during the operation. Documentation is essential for further analysis and project reporting.

Common Issues and Troubleshooting

As with any equipment, you may face some common issues while using a tachometer on a centrifuge. Here are some solutions:

- Inaccurate Readings: Ensure that the tachometer is calibrated correctly before taking measurements.

- Device Malfunctions: If the tachometer fails to read, inspect the connections or battery status.

- Reflective Surfaces: For non-contact models, make sure the surface is clean and reflective enough for accurate reading.

Best Practices for Using a Tachometer

To make the most out of your tachometer during centrifuge operation, keep the following best practices in mind:

- Always consult the user manual for both the tachometer and the centrifuge to ensure accuracy.

- Regularly calibrate and maintain your tachometer for consistent performance.

- Use protective gear when operating high-speed centrifuges for safety.

Final Thoughts

Knowing how to use a tachometer on a centrifuge is paramount for tech aficionados and professionals alike. Not only does it ensure peak performance, but it also guarantees accurate results in your experiments. For further reading, check out this informative piece on tachometers in laboratory settings. With diligent practice, you can master this essential skill and contribute effectively to your technological endeavors.

FAQs about Tachometers and Centrifuges

- What is the purpose of a tachometer? A tachometer measures the rotational speed of equipment, ensuring optimal performance.

- Can a tachometer be used on any centrifuge? Yes, as long as it is compatible with the specific design and specifications of your centrifuge.

- How often should a tachometer be calibrated? Regular calibration is recommended at least once a year, or as specified by the manufacturer.