When is the Tachometer Used? Key Applications Explained

Share

The tachometer is an essential instrument in the worlds of engineering and automotive technology. But when is the tachometer used? This device measures the rotational speed of an object, typically a shaft or disk, and is a crucial tool for tech professionals and enthusiasts alike.

In this article, we will delve into the various contexts in which tachometers are utilized, their significance, and how they contribute to efficiency and safety in various applications. By the end of this exploration, you will have a comprehensive understanding of the tachometers roles across different industries, ensuring you know exactly when its best employed.

What is a Tachometer?

A tachometer is a device that measures the rotational speed of an object, providing readings typically in revolutions per minute (RPM). It can be mechanical or digital, capable of displaying real-time data to the user. Understanding the workings of a tachometer is critical for its effective application.

For a more detailed comprehension of how a tachometer operates, you may refer to this resource: How Does it Work?.

Key Applications of Tachometers

There are numerous instances where a tachometer is essential. Here, we'll explore some of the key scenarios:

1. Automotive Industry

In vehicles, tachometers are crucial for monitoring engine performance. By providing the driver with real-time data, it helps in optimizing gear changes and ensuring the engine operates within safe limits. This application is paramount in performance vehicles, where precision in RPM can significantly enhance speed and efficiency.

Furthermore, the tachometer interfacing with an engine control unit (ECU) can lead to better performance tuning. For a deeper understanding of its role in automotive systems, check out our article on Primary Purpose of Tachometer.

2. Industrial Equipment

In industrial settings, tachometers help monitor the speed of motors and machinery. Keeping machines running at an optimal speed can prevent wear and tear and prolong their lifespan. Moreover, this measurement allows for better control of processes, making sure everything operates smoothly.

Tachometers in manufacturing can also be crucial for safety. By ensuring machinery operates within its designated RPM, the risk of accidents can be substantially reduced. For troubleshooting and testing industrial tachometers, refer to our guide on Testing Signals.

3. Aviation and Aerospace

Tachometers are also widely used in aviation and aerospace applications. They are critical for monitoring the rotational speed of engines, ensuring they do not exceed the manufacturers specifications. Pilots need this data to maintain engine performance and safety during flight.

In helicopters, tachometers help monitor rotor speed, which is vital for stable flight. If you want to learn more about aviation tachometers, visit this article on Tachometers in Aviation.

4. Marine Applications

In marine vessels, the tachometer plays a significant role in engine management. Much like cars and planes, maintaining the right RPM in boats is crucial for fuel efficiency and performance. Tachometers provide real-time data to ensure vessels operate within safe speed ranges.

Using a tachometer can significantly enhance maneuverability and response in various marine operations, making it an invaluable tool in this sector.

Advanced Features of Modern Tachometers

With technological advancements, modern tachometers have incorporated sophisticated features that enhance their usability:

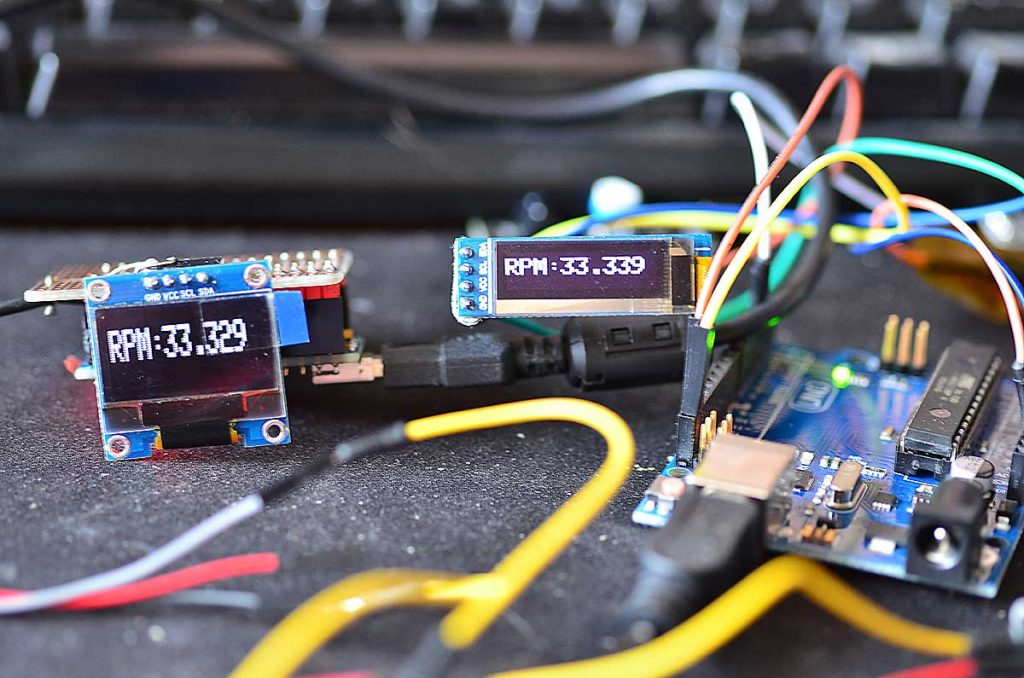

1. Digital Displays

Many modern tachometers now feature digital displays, providing clearer and more precise readings compared to traditional analog versions. This allows for quick assessments and facilitates decision-making based on real-time data.

2. Integration with Other Instruments

Todays tachometers can often integrate with other instruments, like speedometers and data loggers. This results in a comprehensive monitoring system that can track multiple parameters simultaneously, improving overall efficiency.

3. Connectivity Capabilities

Some tachometers now include connectivity options, enabling data sharing with smartphones and other devices for remote monitoring. This feature is particularly appealing for tech enthusiasts interested in the Internet of Things (IoT).

How to Measure Tachometer Effectiveness

Evaluating the effectiveness of a tachometer is crucial for maintaining its accuracy. Here are some methods to test tachometers:

1. Visual Inspection

A simple visual check can often reveal wear or damage. Ensuring that the display is functioning and items such as wires are intact is vital.

2. Signal Testing

Using a multimeter to test the tachometer signal is an essential skill. This process can help determine if the tachometer is sending accurate readings. For a detailed guide on testing signals, see our comprehensive article here: Signal Testing Guide.

3. Bench Testing

Bench testing a tachometer allows for an in-depth examination of its operational parameters under controlled conditions. To learn how to effectively conduct bench tests, read up on our resource: Bench Testing Methods.

Conclusion: Understanding When to Use a Tachometer

In conclusion, understanding when is the tachometer used is crucial for anyone involved in machinery and engine operation. Its applications span across numerous industries, providing invaluable data that enhances efficiency and safety. As technology evolves, the role of the tachometer is set to expand even further, making it an exciting time for tech professionals and enthusiasts alike.

FAQ

1. What industries use tachometers?

Tachometers are used in automotive, industrial, aviation, aerospace, and marine sectors.

2. How do you test a tachometer?

You can test a tachometer by performing visual inspections, signal testing using a multimeter, or conducting bench tests.

3. Can a tachometer be connected to other devices?

Yes, modern tachometers often come with connectivity features that allow integration with smartphones and other monitoring devices.